Understanding batch-to-batch variation in pot ale

IBioIC's Impact Accelerator project helps Glasgow Polyomics reveal the secrets of pot ale variation important for biofuel production

As Scotland paves the way for a future less reliant on petrochemicals, it is becoming pivotal to make bio-based alternatives more efficient and reliable, bringing both environmental and economic viability to the biotechnology sector in Scotland.

Celtic Renewables are a Scottish start up with big plans to transform the way Scotland sources fuel and chemicals. The company have developed a unique process to convert pot ale, produced during whisky fermentation, into advanced biofuels, high-value low carbon chemicals and high protein animal feed, circumventing the need for petrochemicals. This project, funded by IBioIC, used expertise at Glasgow Polyomics to investigate the variation in nutrients and other biochemicals in the pot ale used to produce these high-value products.

Batch failure – is pot ale variation to blame?

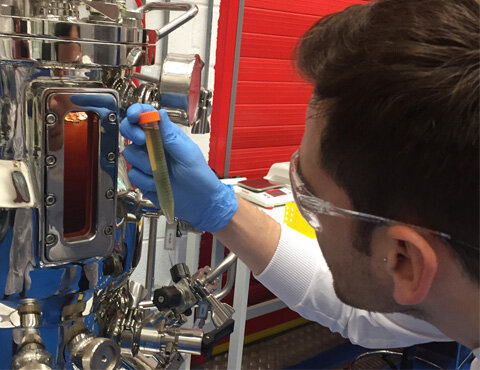

Celtic Renewables uses microbes to turn pot ale into useful products. While the company’s process is very efficient, the traditional industry has historically experienced occasional fermentation failures for reasons that were not fully understood but which were often attributed to substrate variation. Using a technique called “metabolomics”, Glasgow Polyomics investigated variation in the pot ale used as a fermentation substrate.

Making sense of the mixture

Pot ale is composed of a mixture of yeast, bacteria, hops and barley that have been cooked together and distilled. Glasgow Polyomics found the mixture to be very complex and with a large amount of variation between batches that might be due to the plants, microbes, the cooking process or the storage conditions. Some of the molecules vary in line with chemical output and these molecules might be suitable as markers of pot ale fermentation quality.

Pot ale quality control

As a result of this project, Celtic Renewables have established a routine pot ale screening step during their fermentation process. A very large amount of preliminary data was produced by Glasgow Polyomics, which will be further analysed in more detail. Celtic Renewables and Karl Burgess aim to hire an IBioIC funded PhD student to further this project, potentially developing a quality test for pot ale.

To hear more about project funding, contact projects@ibioic.com