Semi-pilot scale harvest of recombinant cells for CDI drugs treatment analytics

Investigation of harvesting strategy of E.coli cells for the production of a novel treatment against Clostridium difficile infection (CDI).

Business Challenge

Clostridium difficile is a bacterium present in the gut of up to 3% of healthy adults and up to 60% of babies where it lives harmlessly. Problems arise for patients taking antibiotics which kill both bad and good bacteria in the gut. This disruption to the gut flora allows C. difficile to multiply, produce toxins and cause its characteristic symptoms of diarrhoea, intestinal inflammation and sometimes serious illness. C. difficile infection (CDI) is a relatively common intestinal disease with over 14,000 cases a year in England and Wales and it is associated with over 1,600 deaths. At present, there are no preventative treatments for CDI on the market, and antibiotics are the only treatment for the initial infection.

Public Health England and MicroPharm Limited (Flynn Pharma) have been collaborating since 2008 to explore a non-antibiotic treatment for this infection. From this collaboration, immunotherapies have been developed, based on polyclonal antibodies, to treat CDI. The antibodies neutralise C. difficile toxins A and B in the gut to alleviate the symptoms. The antibodies employed in the treatment are raised in sheep using recombinant fragments of toxins A and B as antigens. These non-toxic proteins are expressed in E. coli and purified before being used to immunise the sheep. The immunotherapies are reaching the end of pre-clinical development and approaching clinical trial.

The first aim of the project was to replicate a fermentation-based expression of the C. difficile recombinant toxin-based antigens to assess whether the production of the recombinant fragments can be easily outsourced to a third-party manufacturer.

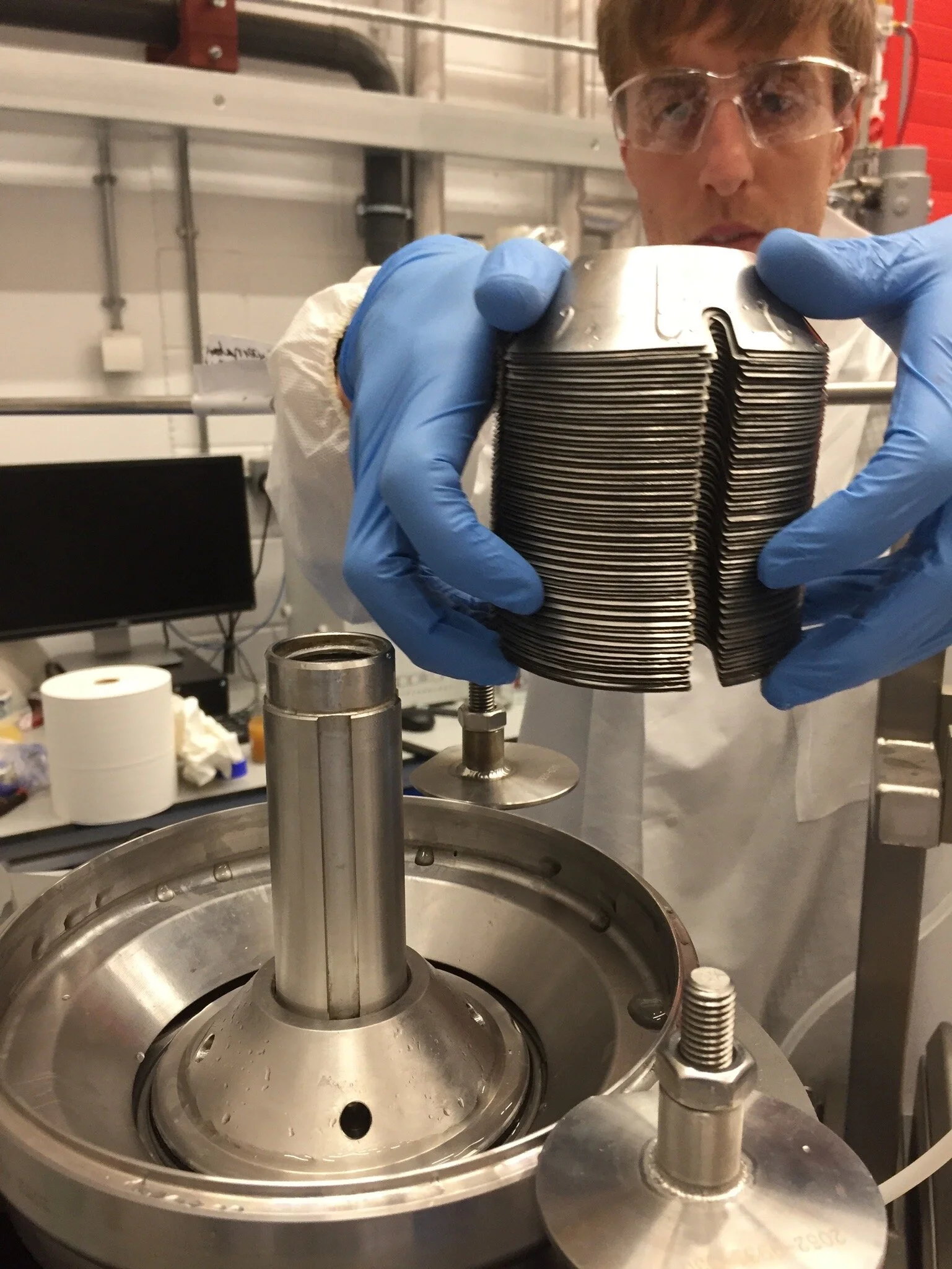

For large-scale manufacturing of the drug, it is necessary to investigate the effect of the downstream processing of the recombinant proteins in an industrial context. To date, the downstream processing has been mainly carried out using small volumes in an R&D laboratory set-up (batch centrifugation). In an industrial context, the harvesting step is commonly carried out using a continuous disk-stack centrifuge. Although similar, the two processes work differently and different shear forces are applied on the biomass. Hence, the second aim of the study was to assess possible adverse effects on the expressed protein using a disk stack centrifugation either on the conformation of the protein fragment or on the yield of purified product.

Solution

The FlexBio Equipment Centre provided PHE access to a semi-pilot scale 30L Applikon bioreactor and a GEA Clarifier disk stack centrifuge. Two experiments were carried out by IBioIC staff members based on in-house upstream and downstream expertise and PHE protocols.

The experiments were designed to adjust the parameters to ensure the transferability of the upstream process to a third party while providing two batches of biomass treated under batch centrifugation and disk stack continuous centrifugation.

Results

Similar protein yields were achieved when compared to a previous large-scale campaign performed at PHE (100L), showing that the upstream process is robust and easily transferable to a third-party after adjusting some parameters conditions such impeller tip speeds. In addition, the yields of the recombinant proteins doubled after using the disk stack centrifuge when compared to batch centrifugation, suggesting that the disk stack centrifuge harvesting technique improves protein extraction and should be preferred as a downstream processing technique. On-going studies at PHE are investigating if any adverse effects on the functionality of the fragments may have occurred.

Benefits

The project confirmed that full scale-up can be achieved and outsourced to a third-party manufacturer at potentially lower economic cost than expected (double extracted protein yield when using disk-stack). A second study will be carried out in late May and early June to confirm the result and repeat the experiment with the second recombinant protein to ensure that the full process is entirely scalable.

Testimonial

I have been very impressed with the work done by IBioIC . They have undertaken the work promptly and professionally. Communication has been excellent between us and I have been kept informed of progress, results or any issues in a timely manner. I am happy that I have been able to obtain further funding to extend the project.

Dr April Roberts, Senior Research Project Manager, Public Health England