Evaluation of Fish Waste as a Novel Feedstock for the Bio-production of Adipic Acid in Escherichia Coli

Turning low value fish waste into high value molecules using biotechnology.

Introduction

Adipic acid is used to make polymers like nylon. Currently, it is made by a process that often involves compounds and solvents derived from petrochemicals, along with the heavy use of nitric acid. Because of its widespread use, it’s important to find a more sustainable way to make adipic acid.

Challenge

Impact Solutions wanted to find a new way to make adipic acid and remove the reliance on fossil fuel-based methods of production.

Solution

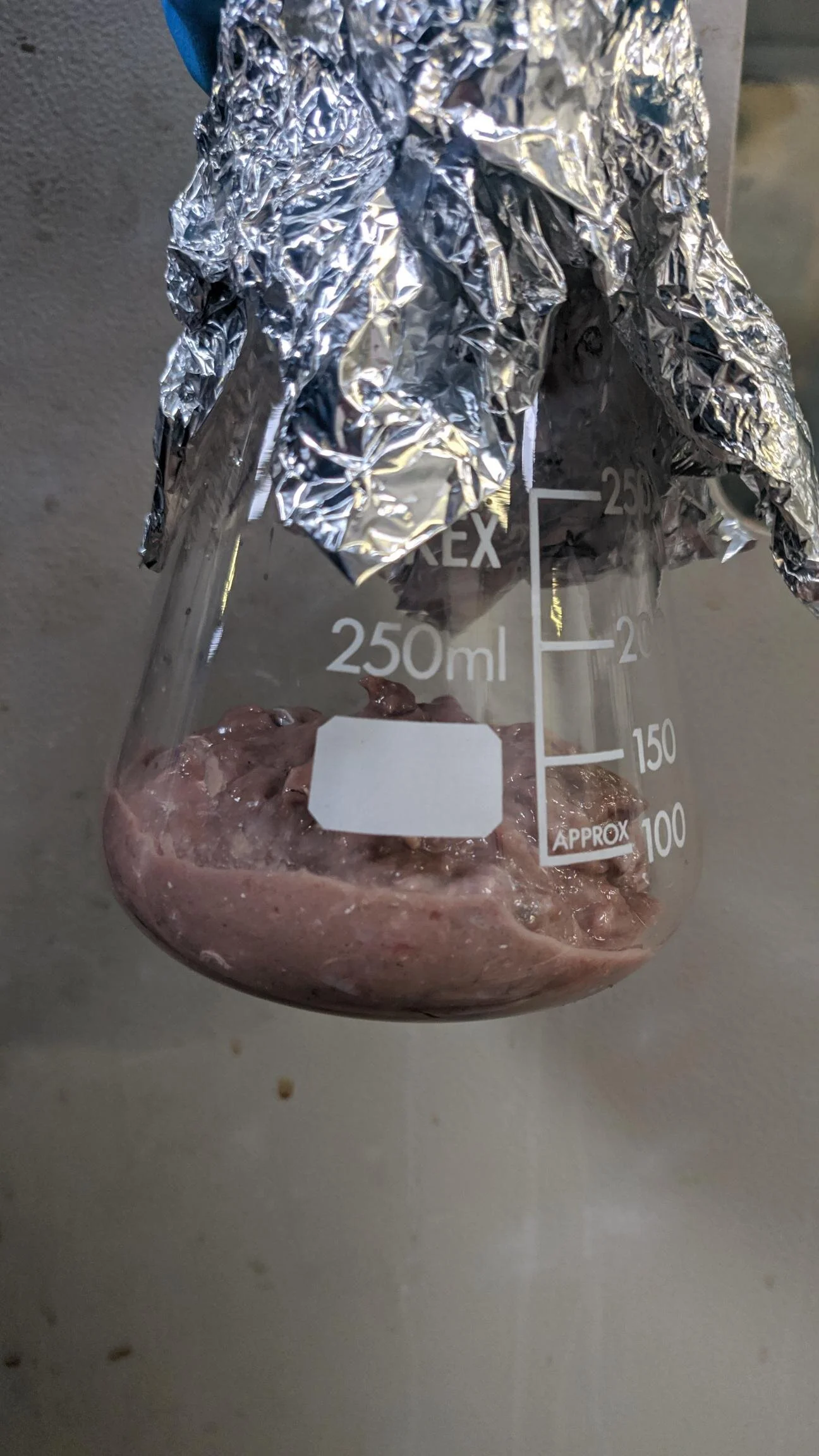

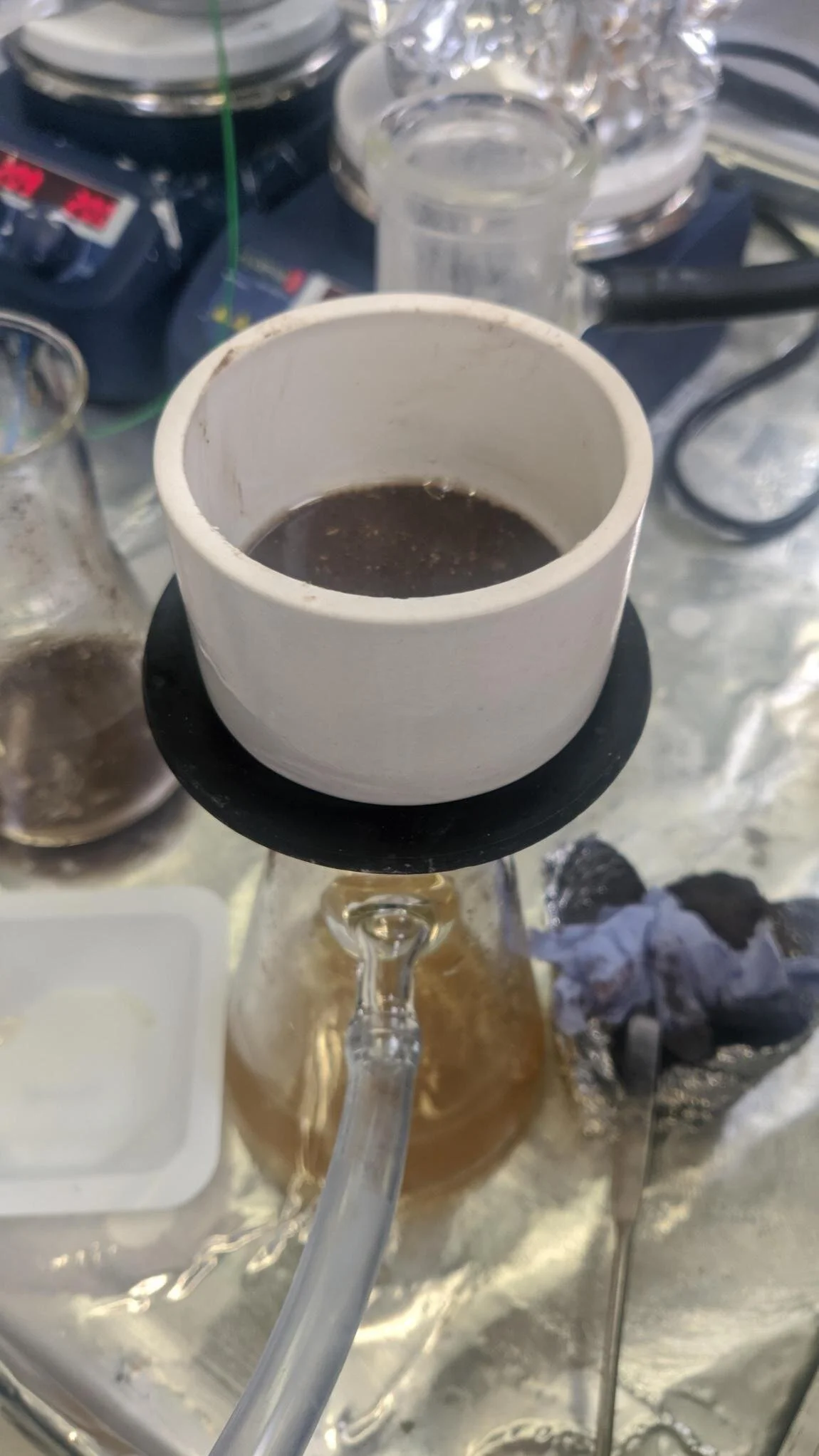

IBioIC funding enabled Impact Solutions and Stephen Wallace at the University of Edinburgh to team up to find a way to use fish waste products and convert molecules enzymatically to adipic acid.

Impact Solutions performed a market analysis on fish waste stream and discovered that some forms of the waste is of such little value that fish processors actually pay to dispose of it. They developed a process to remove compounds from the waste and provided these enriched samples of compounds that can be used as feedstocks for engineered bacteria to UoE, who then identified the enzymes needed to convert the compounds to adipic acid.

Outcome

A new, green, route to producing a valuable industrial chemical was demonstrated using a biotechnology process and a previously zero-value waste stream. Impact Solutions identified new biomass potential and the company and UoE established a new collaboration which will apply for further funding. Training was also generated for a PhD student who was seconded to the project.